Quick Summary

Choosing between a brushed and a brushless DC motor really depends on what matters most in your project.

- Efficiency: Brushless DC motors (BLDC) convert more power into motion — often above 85–90%.

- Maintenance: Brushed DC motors (PMDC) need brush replacement over time; BLDCs are virtually maintenance-free.

- Lifespan: Brushless designs last significantly longer, limited mostly by bearings.

- Cost: Brushed motors are cheaper upfront; brushless saves money over time.

- Control: Brushed = simple voltage or PWM; Brushless = precise electronic driver.

In short:

- If you value simplicity and low cost, go with a brushed motor.

- If you need efficiency, quiet operation, and long life, go brushless.

Understanding the difference between brushed and brushless DC motors is one of the most important steps in selecting the right drive system.

This comparison affects everything — efficiency, cost, maintenance, and long-term performance — all key factors whether you’re sourcing motors for industrial equipment, consumer devices, or automation systems.

In this article, we’ll break down the practical differences between the two types and help engineers, purchasing managers, and project leads make confident decisions for their projects.

What is a Brushed DC Motor?

A brushed DC motor (PMDC) uses carbon brushes and a commutator to deliver current to the rotor windings. It’s the oldest yet still one of the most widely used DC motor types.

Key Advantages:

- Simple structure and low production cost

- Easy speed control via voltage or PWM

- Available in many sizes and voltages

Typical Applicationss:

- Automotive parts (window lifters, seat adjusters)

- Household tools and appliances

- Entry-level pumps, fans, and simple automation

Learn more about our Brush Gear DC Motor Series or Brushed DC Motor Options

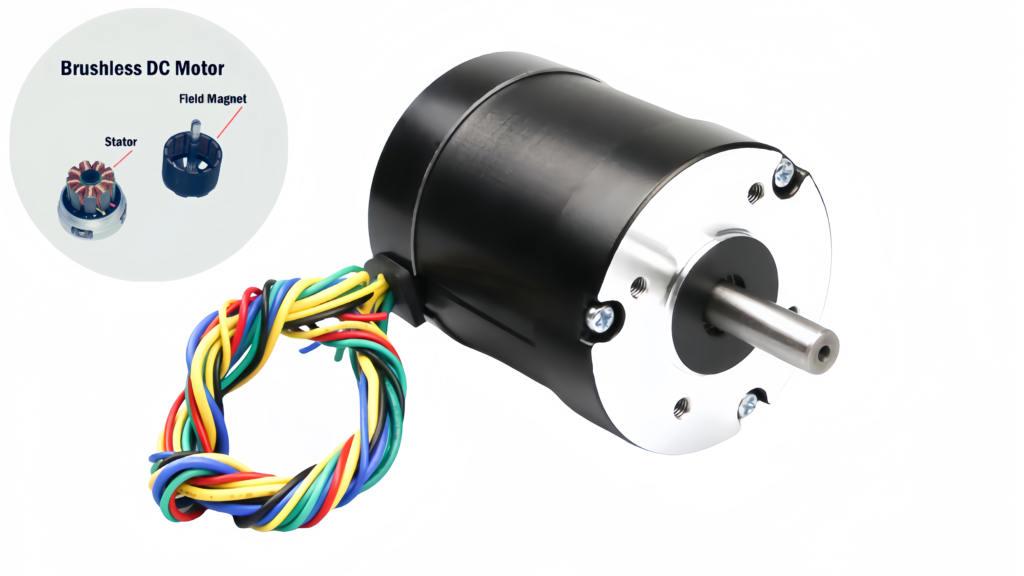

What is a Brushless DC Motor?

A brushless DC motor (BLDC) replaces mechanical brushes with electronic commutation. Permanent magnets on the rotor and sensors in the stator enable precise, efficient control.

Brushless DC motors (BLDC) use electronic commutation rather than physical brushes. They incorporate permanent magnets and advanced control electronics to deliver power more efficiently and precisely.

Key Advantages:

- Higher energy efficiency and torque per watt

- Quieter operation and minimal wear

- Long lifespan with low maintenance

Common Uses:

- Robotics and automated equipment

- Electric vehicles and drones

- Medical and laboratory devices

- Renewable-energy systems

Learn more about our BLDC Motor Series

Brushed vs Brushless DC Motor Comparison

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Efficiency | Lower, brush friction reduces output | Higher, minimal internal losses |

| Maintenance | Brushes wear over time | Nearly maintenance-free |

| Lifespan | Shorter (brush wear) | Longer (bearing-limited) |

| Noise Level | Moderate to high | Very quiet |

| Initial Cost | Lower upfront | Higher, but long-term savings |

| Speed Control | Simple PWM/voltage | Precise electronic control |

| Driver requirement | None required | Needs BLDC driver |

| Low-speed smoothness | Moderate | Very smooth with FOC/Sine drive |

| Total cost over time | Low start cost, higher upkeep | Higher start cost, lower upkeep |

Table: Comparison of brushed vs brushless DC motors across efficiency, maintenance, and cost.

Which One Should You Choose?

- Choose a brushed DC motor if your project is cost-sensitive, runs at low to moderate duty, and you prefer simple control (e.g., pumps, fans, small tools).

- Choose a BLDC motor (brushless DC motor) if you need higher efficiency, long service life, and quiet/precise control under variable loads (e.g., medical devices, robotics, battery-powered systems).

- If space is limited or downtime is costly, a BLDC motor is usually the smarter investment.

- For high torque at low speed with basic electronics, a brushed gear DC motor can often be sufficient.

Still unsure which motor best fits your design?👉 Talk to our engineers or explore our PMDC, Gear DC, and BLDC motor options to find the right match for your application.

FAQs: Brushed vs Brushless DC Motors

🔹 Are brushless motors always better than brushed motors?

Not necessarily. While brushless motors are more efficient and require less maintenance, brushed motors are often more cost-effective and suitable for simple or low-duty applications.

🔹 Which lasts longer, brushed or brushless DC motor?

Brushless DC motors typically last much longer because there are no brushes to wear—life is mainly limited by bearings and heat. A well-used brushed motor may need brush replacement during service; with proper maintenance it can still run reliably, but BLDC usually delivers the longest overall life.

🔹 Can I upgrade from a brushed motor to a brushless one in the same system?

It depends on your controller and space. Brushless motors often need a compatible driver/controller and may differ in size or mounting requirements.

🔹 Which motor type is quieter in operation?

Brushless motors are generally much quieter than brushed motors because there’s no friction from brushes.

🔹 Do brushless motors require any maintenance at all?

They require very little, but proper heat dissipation and controller matching are important to extend lifespan.

Summary

Understanding the difference between brushed and brushless DC motors helps you make smarter decisions when it comes to efficiency, cost, and reliability.

At RUITO, we provide both motor types in various configurations, ready to fit your needs.

Explore our full range:

Related Articles: