Quick Checklist(Before You Start)

If you only have a minute, here are the core maintenance habits that prevent most early motor failures:

- ✔ Inspect brushes & commutator (for brushed DC motors)

- ✔ Check bearings for noise or vibration

- ✔ Keep vents and airflow paths clear

- ✔ Monitor motor temperature under load

- ✔ Follow FIFO and maintain accurate storage/maintenance records

These five alone can significantly extend the service life of a DC motor.

Why DC Motor Maintenance Matters

DC motors support everything from conveyors and pumps to medical devices and lab automation systems. But even a high-quality motor can fail early if airflow is blocked, bearings dry out, brushes wear unevenly, or insulation absorbs moisture.

A solid maintenance routine prevents downtime, avoids unnecessary repairs, and ensures stable long-term performance. Below are 10 essential practices used by engineers to keep DC motors in reliable condition.

10 Essential DC Motor Maintenance Tips:

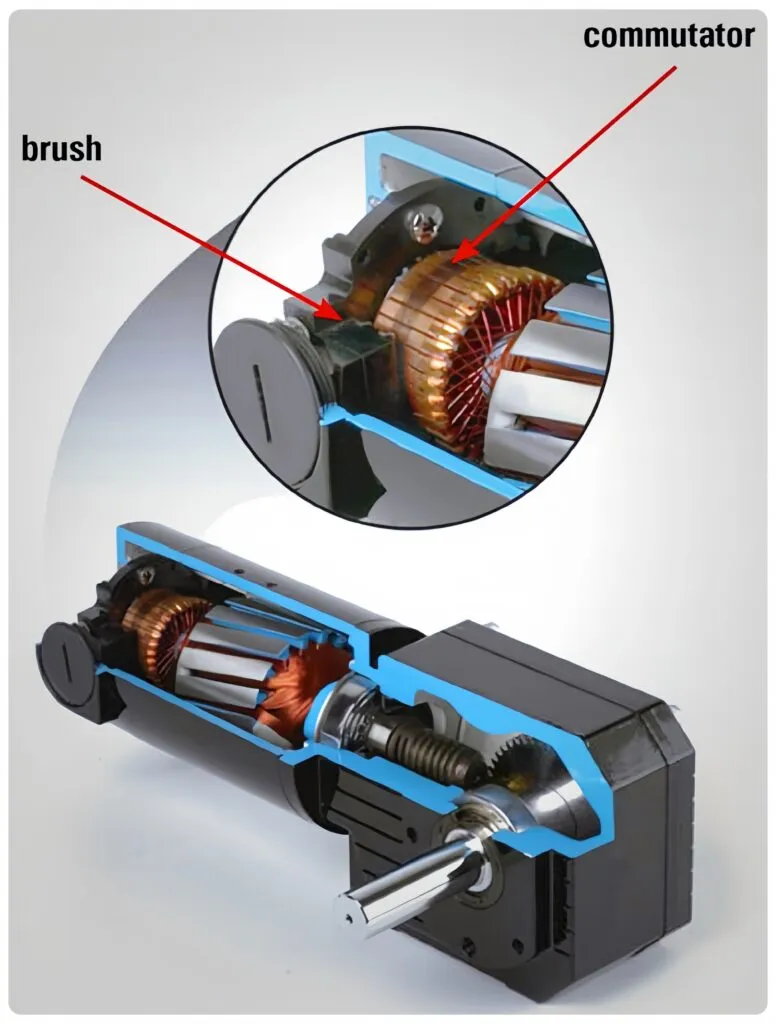

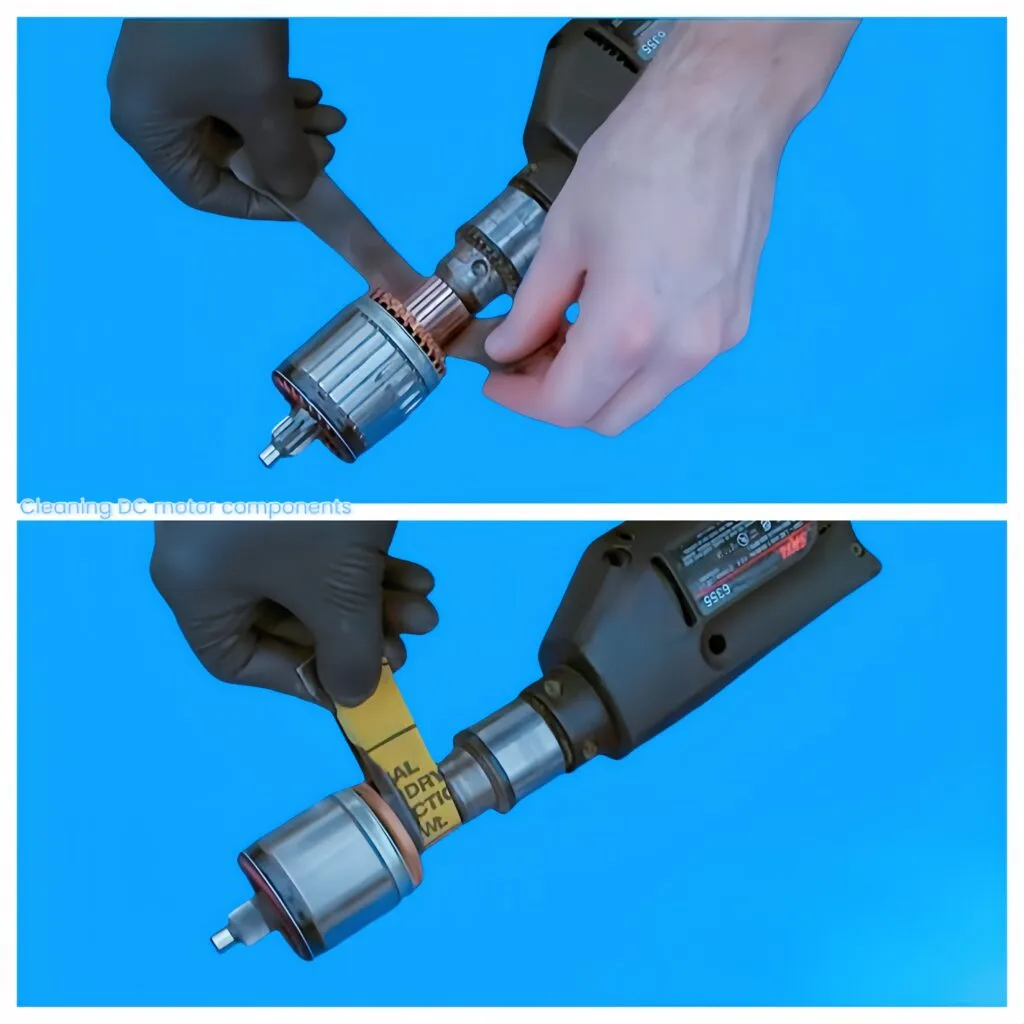

1. Inspect Brushes and Commutator Regularly

(For brushed DC motors)

Why it matters:

Brush wear and commutator contamination are the most frequent causes of arcing, sparking, and reduced torque output.

What to do:

- Inspect brushes every 500–1000 hours

- Replace them before reaching minimum length

- Clean the commutator with a fine abrasive to maintain smooth surface contact

What happens if you don’t:

Underperformance, sparking, overheating, and eventual motor failure.

2. Check for Bearing Noise and Vibration

Why it matters:

Clicking, grinding, or irregular vibration signals bearing wear, misalignment, or insufficient lubrication.

What to do:

- Listen during startup and under load

- Check for shaft play or runout

- Use vibration analysis tools if available

What happens if you don’t:

Bearing damage spreads to the rotor and shaft, causing more serious mechanical failure.

3. Measure Insulation Resistance Periodically

Why it matters:

Low insulation resistance indicates moisture, contamination, or insulation degradation.

Make sure the motor is fully disconnected from power before testing insulation resistance.

What to do:

- Use a megohmmeter between windings and motor frame

- Test during scheduled downtime, especially in humid environments

What happens if you don’t:

Silent electrical degradation can lead to short circuits and unplanned shutdowns.

4. Keep Vents and Cooling Paths Clear

Why it matters:

Dust and debris reduce airflow, causing temperature rise.

What to do:

- Use dry compressed air to clean vents and louvers

- Increase cleaning frequency in dusty or oily environments

What happens if you don’t:

Overheating accelerates insulation aging and damages bearings.

5. Monitor Motor Temperature Under Load

Why it matters:

Continuous operation above rated temperature drastically shortens motor life.

What to do:

- Use infrared thermometers or built-in sensors

- Compare readings with rated max temperature

- Correct airflow or load issues if temperature rises abnormally

What happens if you don’t:

Insulation breakdown, torque loss, and increased failure risk.

6. Tighten All Electrical Connections

Why it matters:

Loose connections cause voltage drops, arcing, and unstable performance.

What to do:

- Tighten terminals on motors and controllers

- Inspect for corrosion or discoloration

What happens if you don’t:

Heat buildup and sudden system failures.

7. Align Motor and Load Correctly

Why it matters:

Misalignment adds mechanical stress and accelerates bearing wear.

What to do:

- Use laser or dial indicator tools for alignment

- Inspect coupling condition

What happens if you don’t:

Higher vibration, increased energy consumption, and premature bearing failure.

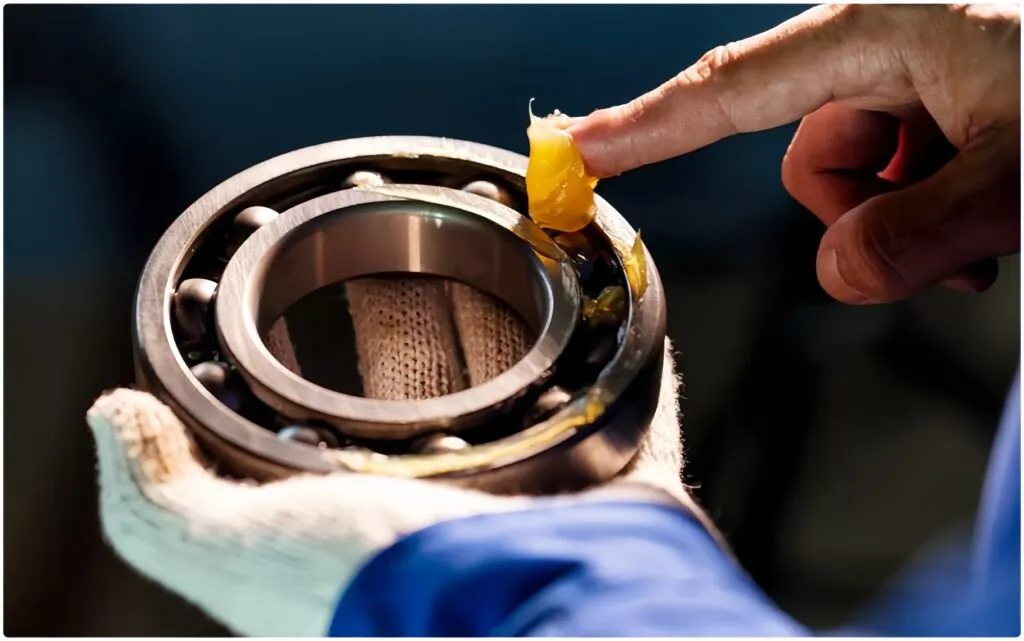

8. Lubricate Bearings per Manufacturer Guidelines

Why it matters:

Too little lubrication = friction.

Too much lubrication = overheating and grease breakdown.

What to do:

- Use correct grease type and intervals

- Avoid over-greasing sealed bearings

What happens if you don’t:

Bearing seizure and costly repairs.

9. Use Correct Motor Protection Devices

Why it matters:

Overload relays, fuses, and thermal sensors prevent preventable failures.

What to do:

- Verify correct protection settings

- Test overload trip response periodically

What happens if you don’t:

Motors may run under dangerous electrical or thermal conditions.

10. Keep Maintenance & Storage Records (and Follow FIFO)

Why it matters:

Poor storage practices can damage motors before they ever enter service. Humidity, long idle periods, and non-FIFO usage often lead to failures that are easily misinterpreted as manufacturing issues.

What to do:

- Maintain logs of inspections, repairs, and test readings

- Track storage dates and always follow FIFO

- Store motors in dry, temperature-stable environments

- For motors stored 6–12 months, rotate the shaft to prevent lubricant settling

What happens if you don’t:

Premature bearing noise, reduced insulation resistance, and startup failures.

Summary – What These 10 Tips Help You Avoid

Applying these practices helps you:

- Extend motor lifespan

- Reduce unplanned downtime

- Improve efficiency and reliability

- Avoid unnecessary repair costs

- Maintain safer and more stable operation

A consistent maintenance routine keeps motors performing at their best across all applications. Whether the motor runs continuously or intermittently, these practices help maintain predictable performance over its full service life.

FAQs

1. How often should DC motors be inspected?

Brushed motors: every 500–1000 hours.

Continuous-duty systems: check bearings, vibration, and temperature monthly.

2. Do brushless DC motors require maintenance?

Yes — bearings and thermal management still require regular inspection.

3. What are the most common causes of DC motor failure?

Overheating, bearing wear, blocked vents, lubrication issues, overload, and improper long-term storage.

4. Can motor lifespan be extended without replacing parts?

Yes — keep airflow clean, monitor temperature, use correct lubrication, and avoid overload conditions.

5. Should I repair or replace a failing motor?

Brush wear and bearing issues are economical to repair.

Severe winding or insulation failures usually justify replacement.

Need Technical Support on Motor Selection or Lifetime Planning?

At RUITO, we work closely with engineering teams to help them choose the right DC motor, evaluate torque and load requirements, estimate lifetime, and optimize thermal performance.

If your application involves continuous duty, variable-speed control, or long service life expectations, our engineers can help ensure the motor is properly sized and configured from the start.

Talk to our engineers for technical guidance or to evaluate the right motor configuration for your project.

Related Articles:

- 🔗 How to Choose the Right DC Motor for Your Application?

- 🔗 Brushed vs Brushless DC Motors – Key Differences

- 🔗 How DC Motors Work – A Beginner’s Guide

- 🔗 How to Control the Speed of a DC Motor

- 🔗 How Many Types of DC Motors Are There?

- 🔗 Why Use DC Motors in Home Automation?

Or explore: