Quick Answer

You can control the speed of a DC motor in three main ways:

- Voltage Control – simple but less efficient.

- Armature Resistance Control – outdated, higher power loss.

- PWM (Pulse Width Modulation) – precise, efficient, and the modern standard.

Among these methods, PWM control provides the best balance of accuracy, quietness, and efficiency — making it the preferred choice for DC motors in home automation and other smart systems.

Why Does DC Motor Speed Control Matter?

DC motor speed control directly determines performance, efficiency, and reliability — it’s a key factor in nearly every motion-driven system.

From smart home devices to industrial automation and robotics, precise speed regulation allows smoother operation, energy savings, and longer motor lifespan.

In home automation, DC motors are used to power fans, automated blinds, sliding doors, and ventilation systems.

If motor speed is not properly controlled, it can cause overheating, noise, and premature wear — all of which reduce reliability and user comfort.

That’s why engineers and designers working with DC motors for smart home systems pay close attention to speed control methods and their implications.

Common Methods for DC Motor Speed Control

There are three main techniques used to adjust the rotational speed of a DC motor. Each has its pros and cons in terms of cost, complexity, and performance.

| Method | How It Works | Best For |

|---|---|---|

| Voltage Control | Varies the supply voltage to change speed linearly. | Simple, low-cost systems. |

| Armature Resistance Control | Adds external resistance in series to reduce voltage across the armature. | Legacy systems; seldom used today. |

| PWM (Pulse Width Modulation) | Rapidly switches supply voltage to control the average effective voltage. | Modern automation and smart home devices. |

How PWM Speed Control Works

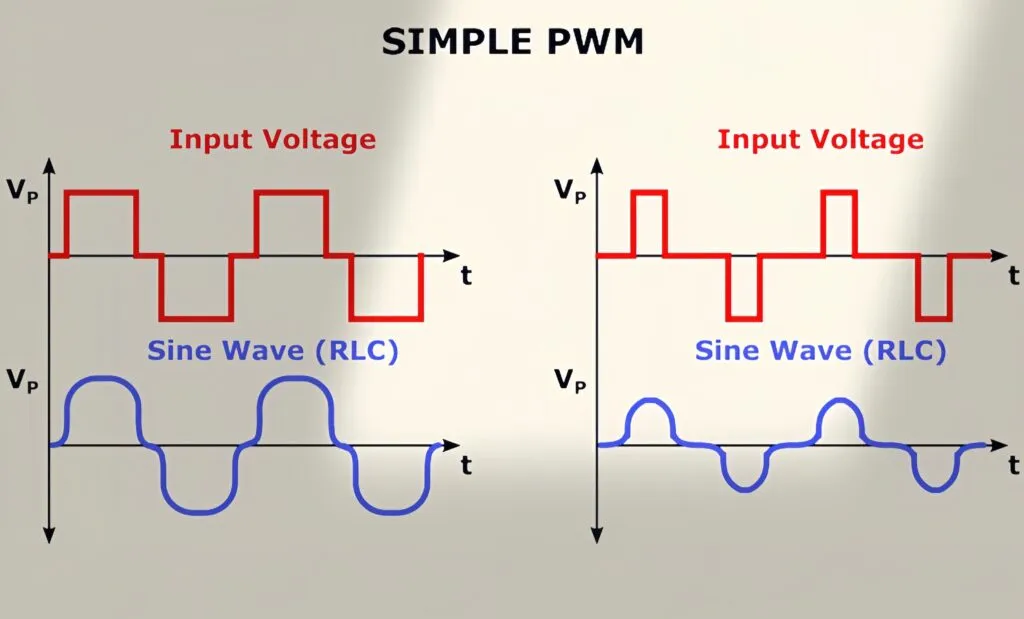

PWM (Pulse Width Modulation) is the most efficient way to control DC motor speed, using rapid voltage pulses to adjust the effective power.

The ratio between “on” and “off” time—called the duty cycle—determines how fast the motor spins.

Advantages of PWM:

- High energy efficiency with minimal heat loss

- Smooth and precise speed control

- Reduced electrical and mechanical noise

- Extended motor lifespan due to less wear

- Ideal for integration with microcontrollers and smart devices

PWM Formula

Duty Cycle (%) = ( Ton / (Ton + Toff) ) × 100

Where:

- Ton – time the PWM signal is high

- Toff – time the PWM signal is low

Common Applications:

Smart home fans, motorized blinds, robotic systems, EV cooling pumps, and automation equipment where quiet and precise control is essential.

Using Arduino for PWM-Based Speed Control

A basic DC motor speed control circuit can be built using an Arduino, an L298N motor driver, and a 10k potentiometer.

This setup demonstrates how real-world devices — like smart home DC motor controllers — modulate speed automatically through sensors or user input, using PWM signals.

Hardware:

- Arduino board

- L298N motor driver

- DC motor

- 10kΩ potentiometer

Wiring:

- Connect the motor to the output terminals of the L298N driver.

- Connect the potentiometer to an analog input pin (e.g., A0) on the Arduino.

- Ensure the motor driver is powered correctly and shares a common ground with the Arduino.

Once the wiring is complete, upload the following Arduino code. After uploading, rotate the potentiometer — the DC motor will respond instantly to PWM signal changes, adjusting its speed smoothly.

int motorPin = 9;

int potPin = A0;

int potValue = 0;

int pwmValue = 0;

void setup() {

pinMode(motorPin, OUTPUT);

pinMode(potPin, INPUT);

}

void loop() {

potValue = analogRead(potPin);

pwmValue = map(potValue, 0, 1023, 0, 255);

analogWrite(motorPin, pwmValue);

}

Best Practices for Engineers

- Right-size the motor: Match torque, voltage, and load precisely.

- Use quality drivers: Stable PWM output ensures long motor life.

- Calibrate regularly: Avoid control drift in precision systems.

- Implement safety: Include overcurrent, thermal, and emergency stop protection.

Real-World Applications of DC Motor Speed Control

- Industrial Automation: Maintain conveyor belt speeds precisely with a PWM controller.

- Robotics: Enable accurate movement and torque control.

- Smart Homes: Quiet control of fans, blinds, and pumps.

- Electric Vehicles: Optimize drive performance and range.

- Medical Devices: Ensure stable fluid delivery and smooth actuation.

Learn how our PMDC Motors and Gear DC Motors achieve smooth, reliable speed control across diverse applications.

FAQ: DC Motor Speed Control

Q1: What is the most efficient way to control DC motor speed?

A: PWM control provides precise, energy-efficient performance and is ideal for DC motors in home automation and industrial equipment.

Q2: Can I use a transistor instead of a motor driver?

A: Yes. You can use a MOSFET or NPN transistor as a basic switch, but dedicated drivers provide better control and protection.

Q3: Does PWM cause noise or wear in DC motors?

A: Not when frequency and duty cycle are properly tuned. Correct PWM setup keeps operation quiet and smooth.

Summary

Mastering DC motor speed control gives you the ability to balance performance, efficiency, and reliability — whether for industrial machines or next-generation smart home automation devices.

At Ruito Motor, we design and manufacture brushed, brushless, and geared DC motors that deliver smooth, controllable motion for every type of project.

⚙️ Need help selecting the right DC motor or speed control solution?

👉 Talk to our engineers for tailored support.

Related Articles:

- 🔗 How to Choose the Right DC Motor for Your Application?

- 🔗 Brushed vs Brushless DC Motors – Key Differences

- 🔗 How DC Motors Work – A Beginner’s Guide

- 🔗 How Many Types of DC Motors Are There?

- 🔗 DC Motor Maintenance – 10 Essential Tips

- 🔗 Why Use DC Motors in Home Automation?

Or explore: