BLDC Motors

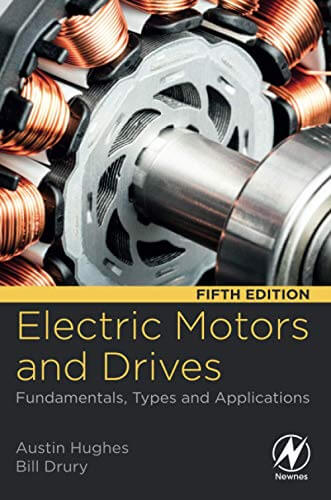

Brushless DC motors (BLDC) offer efficient, quiet, and low-maintenance performance by eliminating the need for brushes. Using electronic commutation and permanent magnets, these motors provide precise control over speed and torque, making them ideal for modern motion systems.

Ruito supplies BLDC motors in compact sizes and various configurations to support a wide range of OEM applications—from automated medical equipment to lab automation, mobility systems, and smart home devices. Our brushless motors can be tailored for different voltage inputs (e.g., 12V, 24V, 48V), speed ranges, and mounting options to match your technical requirements.

Whether you’re looking for a small BLDC motor for space-limited designs or a custom brushless DC motor with integrated gearboxes or encoders, Ruito delivers reliable performance backed by RoHS and CE compliance.